High-Performance Wing Type Rubber Fender for Superior Dock Protection

sfsdfdsgfgdfggggg

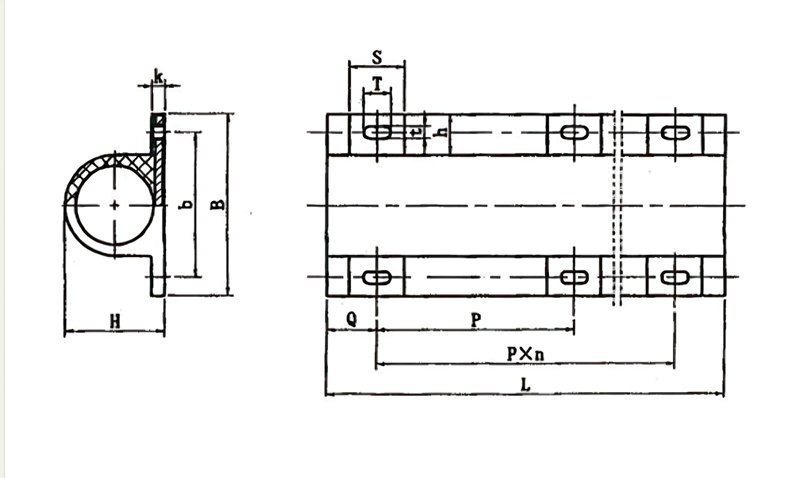

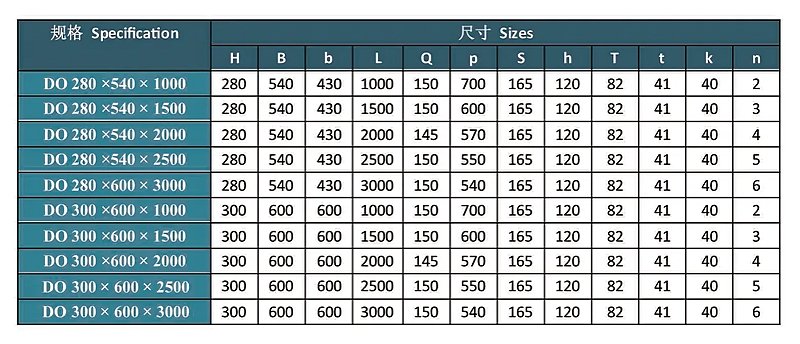

Wing-type rubber fenders are an upgraded version of the traditional D-type rubber fender, designed to provide increased strength, a wider contact surface, and improved energy absorption. The wing-shaped side extensions provide enhanced stability and distribute impact forces more effectively, making them ideal for heavy-duty marine applications such as quay walls, berthing points, and vessel hulls.

Wing Type Rubber Fender Key Features:

-

Upgraded Design: Based on D fenders, with added wing extensions for improved load distribution and wear resistance.

-

Better Energy Absorption: Increased volume and reinforced shape allow for greater energy absorption and lower reaction force.

-

Strong and Durable: Made from high-quality rubber compounds for excellent resistance to UV, saltwater, and aging.

-

Easy to Mount: Can be installed using bolts or adhesive; available with or without pre-drilled holes.

-

Customizable: Lengths, colors, and end designs (flat or beveled) can be customized according to project needs.

Applications:

-

Commercial ports and terminals

-

Container berths and shipyards

-

Vessel sides, quay edges, loading bays

-

Areas requiring upgraded fender performance compared to standard D fenders

Why Choose Our Wing Fenders?

Compared to traditional D-type fenders, our wing rubber fenders deliver higher structural integrity and longer service life. They are ideal for projects that demand reliable performance in high-frequency berthing environments or rough sea conditions.

Technical Data Available Upon Request

We offer detailed drawings, compression load charts, and installation guides to support your engineering needs.

Custom Sizes Available:

We support full customization of sizes and specifications for bulk orders. Please contact us for tailored solutions.

Pre-installation Recommendations:

Note on Pre-bending and Chamfering

For structures with curved surfaces or irregular profiles, fenders may require pre-bending to ensure proper fitment and to avoid stress concentration. Additionally, it is recommended to chamfer both ends of the fender to reduce the risk of edge damage during installation and operation.