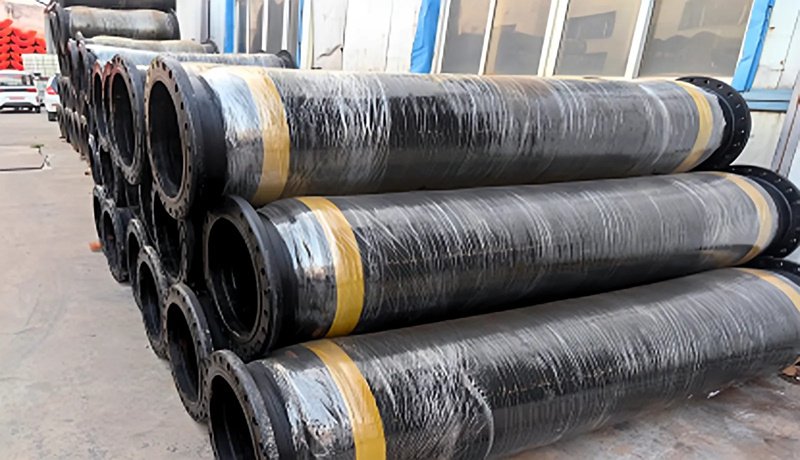

Reinforced Dredge Hose for Submerged and Onshore Applications

Our heavy-duty dredge hose is designed for underwater and shoreline dredging projects: reinforced structure, excellent abrasion resistance, and a 3:1 safety factor for long-lasting performance.

Our dredge hose is specifically designed for fixed or underwater dredging applications where floating performance is not required. Built with multiple layers of high-tensile fabric reinforcement and abrasion-resistant rubber compounds, this hose ensures reliable operation under constant bending, suction pressure, and sediment impact.

Dredge Hose Product Highlights:

- Optimized for Submerged and Onshore Use

Ideal for underwater pipelines, near-shore connections, and non-floating discharge systems. - Anti-Collapse Structure

The hose maintains shape and stability even under negative pressure or repeated bending. - Durable Rubber Inner Layer

Engineered with NR, BR, and SBR for high abrasion resistance when handling sand, silt, and slurry. - Reinforced for Heavy-Duty Work

Multi-layer, high-tensile strength fabrics effectively resist both internal and external pressure. - Safe & Reliable

Safety factor up to 3:1 – well-suited for continuous operations in dredging and land reclamation. - Cost-Effective Option

Compared to floating hoses, it offers a more economical solution for fixed installations.

Typical Applications:

- Underwater suction or discharge pipelines

- Shoreline dredging systems

- Silt and slurry transfer in rivers, ports, and construction zones

- Flood drainage and civil engineering groundwork

Optional Features:

- Custom lengths and diameters

- Steel flanges, rubber cuffs, or quick couplings

- Ceramic or UHMWPE lining for high-abrasion tasks

- External anti-aging coatings for extended service life

Custom Sizes Available:

We support full customization of sizes and specifications for bulk orders. Please contact us for tailored solutions.

Pre-installation Recommendations:

Note on Pre-bending and Chamfering

For structures with curved surfaces or irregular profiles, fenders may require pre-bending to ensure proper fitment and to avoid stress concentration. Additionally, it is recommended to chamfer both ends of the fender to reduce the risk of edge damage during installation and operation.