Durable Floating Dredging Hose for Marine and Offshore Applications

Our Floating Dredging Hose is specially engineered for dredging and slurry discharge operations in open water environments. Designed with built-in flotation layers and a robust wear-resistant inner lining, it ensures long service life and stable performance in challenging marine and dredging projects.

Engineered for Stability, Strength, and Long-Term Performance

Our floating dredging hose is designed to withstand the demanding conditions of dredging projects with superior materials and innovative features. It combines durable rubber compounds, multi-layer high-tensile reinforcement, and excellent floating capability, ensuring safe and efficient transport of seawater, slurry, silt, and sand in harsh marine environments.

Why Choose Our Floating Dredge Hose?

-

Premium Rubber Material

Inner and outer layers made of NR (Natural Rubber), BR (Butadiene Rubber), and CR (Chloroprene Rubber) — offering excellent wear resistance and aging resistance in seawater and abrasive media.

-

Multi-layer Reinforcement

Reinforced with high tensile strength fabrics, providing high pressure resistance and long service life even under strong currents and repeated bending.

-

High Safety Factor (3:1)

Engineered with a 3:1 safety factor, ensuring reliable performance under tough operational conditions and unexpected pressure surges.

-

Wide Working Temperature Range

Reliable operation from -20°C to +80°C, suitable for various climates and water temperatures.

-

Floatation Functionality

Built-in buoyancy layers eliminate the need for external floats, reducing installation complexity and improving maneuverability in water.

Floating Dredging Hose Application Fields

- Port and harbor dredging

- Coastal reclamation projects

- River and lake sediment removal

- Flood control and slurry discharge

- Marine civil engineering and offshore foundation work

Customization Available:

- Different rubber grades for inner/outer layers (e.g., for chemical or extreme abrasion resistance)

- Various flange or coupling types

- Optional extra-thick wear layers for extended service life

- UV- and saltwater-resistant covers for open-sea usage

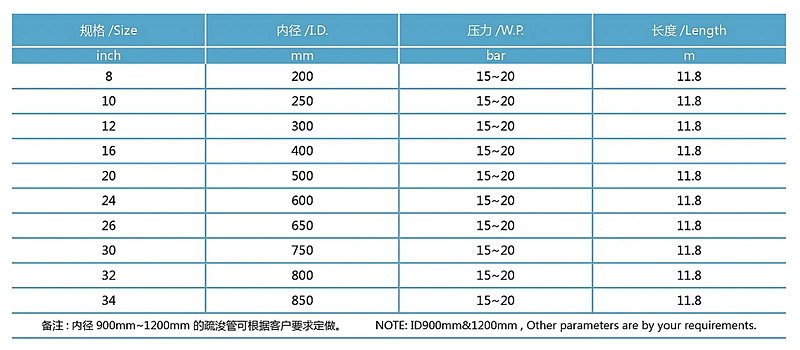

Custom Sizes Available:

We support full customization of sizes and specifications for bulk orders. Please contact us for tailored solutions.

Pre-installation Recommendations:

Note on Pre-bending and Chamfering

For structures with curved surfaces or irregular profiles, fenders may require pre-bending to ensure proper fitment and to avoid stress concentration. Additionally, it is recommended to chamfer both ends of the fender to reduce the risk of edge damage during installation and operation.

Note on Pre-bending and Chamfering

Note on Pre-bending and Chamfering

Note on Pre-bending and Chamfering

Note on Pre-bending and Chamfering