Cylindrical Rubber Fender – High-Performance Marine Fender for Dock & Vessel

Durable and highly efficient, our cylindrical rubber fenders offer reliable energy absorption and easy installation for ports, vessels, and marine structures.

Cylindrical rubber fenders are among the most commonly used fender types for protecting ports and vessels. With their simple design, excellent energy absorption, and ease of installation, they provide reliable performance for a wide range of marine structures.

Cylindrical Rubber Fender Key Features:

-

High Energy Absorption: Capable of handling large impact forces during berthing.

-

Simple Design: Ideal for both vertical and horizontal installations.

-

Versatile Applications: Suitable for quay walls, piers, wharves, and small harbors.

-

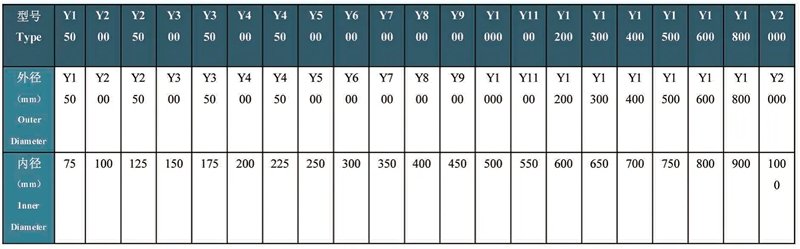

Customizable Sizes: Lengths, diameters, and mounting types can be tailored to your needs.

-

Durable Performance: Resistant to weather, UV, seawater, and mechanical wear.

Typical Applications

-

Commercial ports and terminals

-

Offshore platforms

-

Naval berthing structures

-

Fishing and ferry piers

-

Tug and barge mooring

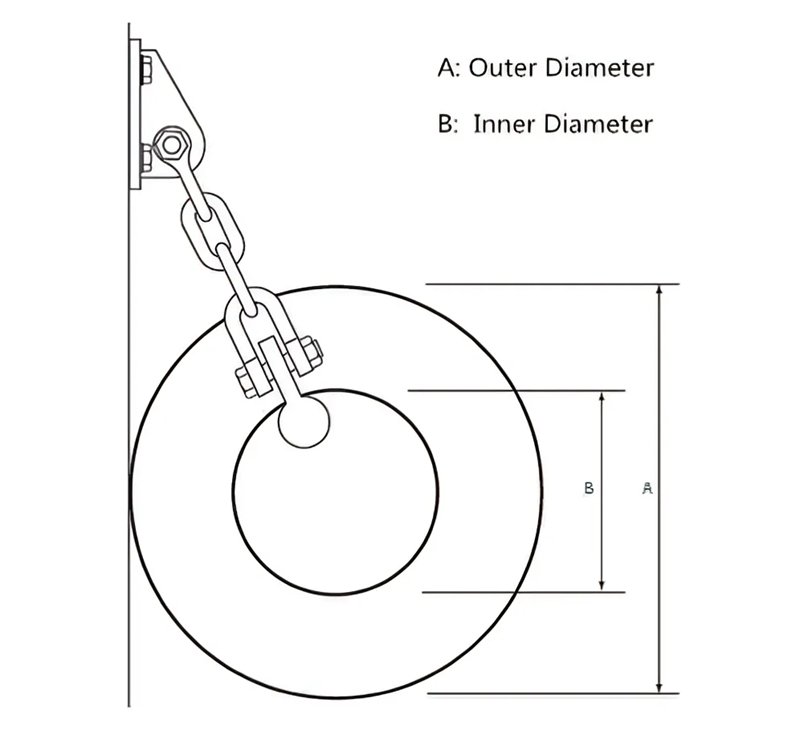

Installation Options

-

Rope suspension or chain support

-

U-bolt or through-rod mounting

-

Can be installed horizontally or vertically

Why Choose Our Cylindrical Fenders?

Our fenders are made from high-quality natural rubber or synthetic compounds, ensuring excellent performance in harsh marine environments. We offer custom fabrication services, including special diameters, lengths, and pre-drilled holes, to suit your engineering project perfectly.

Need help choosing the right size or installation method?

Contact our engineering team now to receive a tailored solution for your port or vessel.

Custom Sizes Available:

We support full customization of sizes and specifications for bulk orders. Please contact us for tailored solutions.

Pre-installation Recommendations:

Note on Pre-bending and Chamfering

For structures with curved surfaces or irregular profiles, fenders may require pre-bending to ensure proper fitment and to avoid stress concentration. Additionally, it is recommended to chamfer both ends of the fender to reduce the risk of edge damage during installation and operation.

Related Products

相关产品

-

Rubber Fender

Custom Arch Rubber Fender for Ports and Harbors