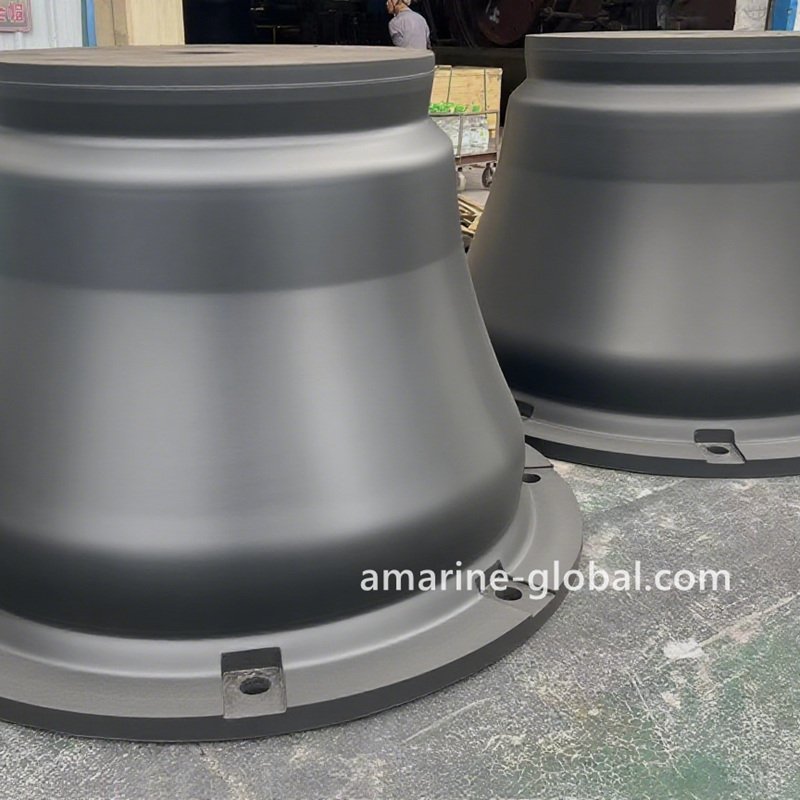

Cone Rubber Fender for Ports and Terminals – Low Reaction, High Performance

With a proven conical geometry and robust structure, our cone rubber fenders offer reliable protection for terminals, ports, and offshore platforms under even the most challenging berthing operations.

If your port handles ultra-large vessels such as VLCCs or LNG carriers, experiences significant tidal variations, or serves as a high-traffic terminal with continuous berthing operations—cone rubber fenders are your most reliable and high-performance solution.

Key Advantages of Cone Rubber Fenders Compared to Other Fender Types

Compared to traditional fender types, cone fenders deliver superior energy absorption, structural stability, and long-term performance, making them the preferred solution for modern port infrastructure.

1. Highest Energy Absorption to Reaction Force Ratio

Cone fenders offer significantly higher energy absorption with lower reaction forces compared to other types, such as arch or cell fenders, providing better protection for both the quay structure and the vessel hull.

2. Greater Deflection Capacity

With the ability to compress up to 70% of their height, cone fenders can absorb large amounts of impact energy without increasing in size—ideal for large vessel berthing.

3. Superior Stability and Shear Resistance

The wide base and conical shape offer excellent resistance to shear forces and torsion, outperforming traditional fenders in demanding berthing conditions.

4. Self-Centering Geometry

The conical design ensures the fender remains stable and properly aligned even under oblique or uneven berthing forces, minimizing structural stress.

5. Excellent for Tidal Variations and High-Frequency Berthing

Cone fenders are well-suited for ports with large tidal ranges or where vessels dock frequently. Their fatigue resistance and durability reduce long-term maintenance costs.

6. Optimized for Large Frontal Panels

Cone fenders are typically used with steel or UHMW-PE frontal panels, allowing pressure to be evenly distributed over the hull surface and reducing the risk of localized damage.

7. Extended Service Life

Manufactured using high-quality, UV-resistant, and marine-grade rubber compounds, cone fenders perform reliably over long periods in harsh marine environments.

Applications

- Container terminals and general cargo wharves

- Oil and gas berths

- RoRo and cruise terminals

- Offshore platforms

- Naval and defense ports

Why Choose Our Cone Fenders

At Amarine Global, we manufacture cone rubber fenders using precision molding technology and rigorous quality control. Each fender is engineered according to international standards such as PIANC and ISO 17357, ensuring consistent performance and durability.

Whether you’re upgrading an existing port or building a new terminal, our cone fenders provide a reliable, low-maintenance solution tailored to your berthing energy needs.

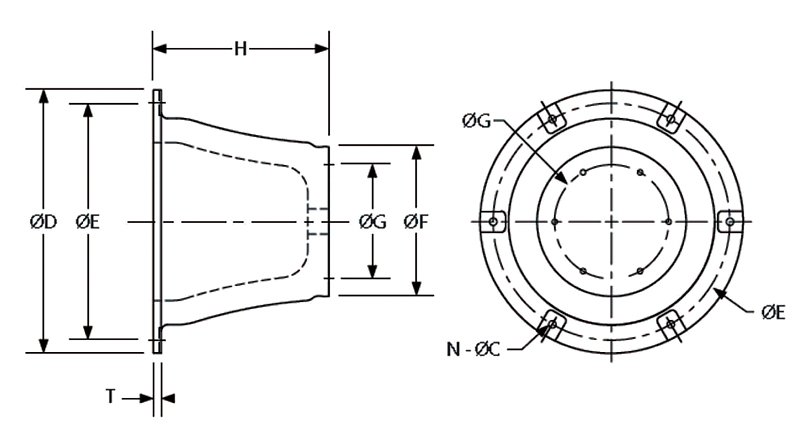

Technical Support & Customization

Our engineering team provides full support from design consultation to onsite installation guidance. We also offer custom color, size, and mounting options to match your project’s unique specifications.

Contact Us Today

Looking for a dependable and cost-effective fendering system? Get in touch with our sales team for a free technical proposal and quotation tailored to your port project.

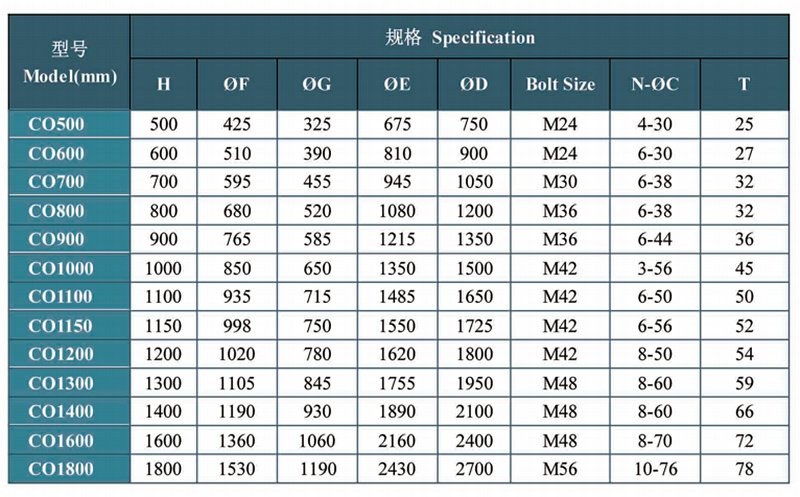

Custom Sizes Available:

We support full customization of sizes and specifications for bulk orders. Please contact us for tailored solutions.

Pre-installation Recommendations:

Note on Pre-bending and Chamfering

For structures with curved surfaces or irregular profiles, fenders may require pre-bending to ensure proper fitment and to avoid stress concentration. Additionally, it is recommended to chamfer both ends of the fender to reduce the risk of edge damage during installation and operation.

Related Products

相关产品

-

Rubber Fender

Custom Arch Rubber Fender for Ports and Harbors

-

Yokohama Pneumatic Fender

Yokohama Fender– Pneumatic Rubber Fender for Marine Protection