Durable Square Rubber Fender – Heavy-Duty Impact Protection

We manufacture high-performance square rubber fenders using premium marine-grade rubber. Each fender undergoes strict quality control, including pre-curving and chamfering upon request, to ensure maximum reliability and lifespan in harsh marine environments.

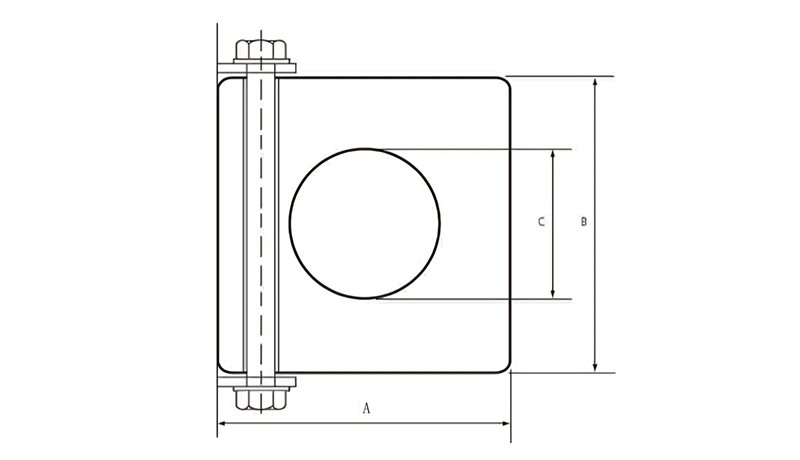

Square rubber fenders, also known as square fenders, are widely used for dock and vessel protection where high durability and large contact surfaces are essential. With a robust square cross-section, they provide excellent energy absorption and minimize pressure on the ship’s hull during berthing operations.

Square Rubber Fender Key Features

- Strong Impact Resistance – Thick square body structure resists heavy collision and abrasion.

- Large Contact Area – Uniform load distribution ensures stable and safe berthing.

- Easy to Install & Replace – Can be mounted vertically or horizontally using bolts or chains.

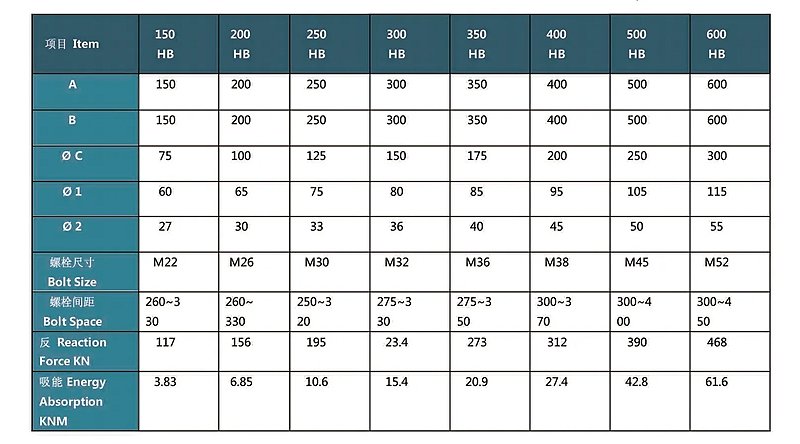

- Custom Sizes Available – Lengths, hole patterns, and end cuts can be customized.

-

Versatile Use: Ideal for small to medium-sized vessels, docks, piers, and quay structures.

-

Optional Pre-Drilled Holes and Chamfered Ends: For enhanced convenience and aesthetic appeal.

Common Applications

- Quay walls and piers

- Tugboats and workboats

- Loading ramps and heavy-duty docks

- Narrow berthing areas

Why Choose Our Square Fenders?

We manufacture high-performance square rubber fenders using premium marine-grade rubber. Each fender undergoes strict quality control, including pre-curving and chamfering upon request, to ensure maximum reliability and lifespan in harsh marine environments.

Custom Sizes Available:

We support full customization of sizes and specifications for bulk orders. Please contact us for tailored solutions.

Pre-installation Recommendations:

Note on Pre-bending and Chamfering

For structures with curved surfaces or irregular profiles, fenders may require pre-bending to ensure proper fitment and to avoid stress concentration. Additionally, it is recommended to chamfer both ends of the fender to reduce the risk of edge damage during installation and operation.

Related Products

相关产品

-

Rubber Fender

Custom Arch Rubber Fender for Ports and Harbors