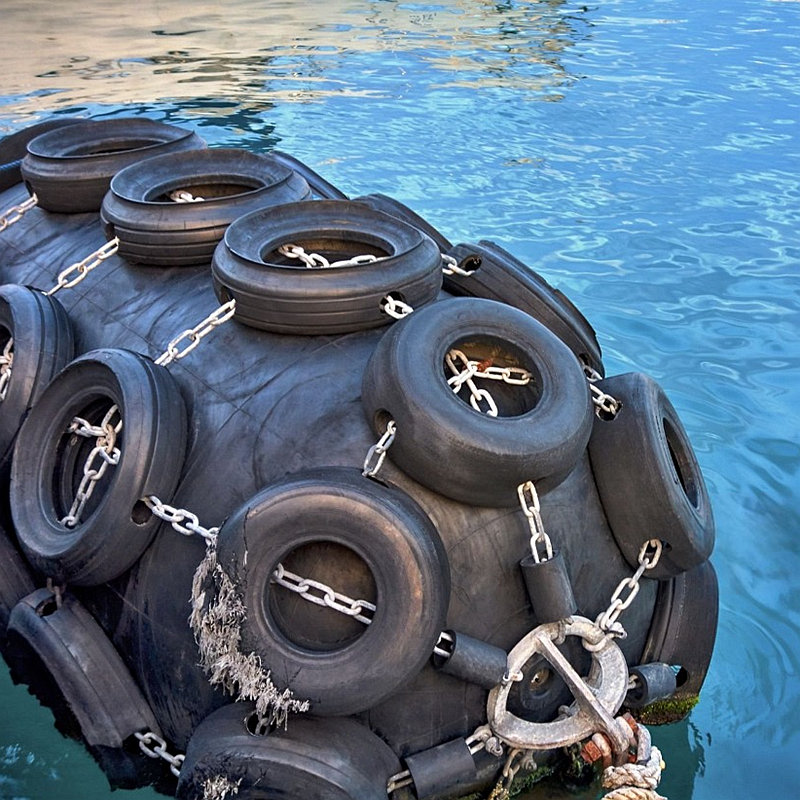

A marine hose is a heavy-duty flexible hose specifically designed for marine engineering, offshore projects, and port operations. It is used to safely transfer oil, water, slurry, or other fluids between ships, offshore facilities, and coastal infrastructure under harsh sea conditions.

Unlike standard industrial hoses, marine hoses are engineered to withstand seawater corrosion, wave-induced movement, UV exposure, and high mechanical stress, making them a critical component in offshore construction, dredging projects, and marine logistics systems.

Typical Marine Engineering Applications

Marine hoses are widely used in engineering-driven and procurement-led projects, including:

- Offshore and nearshore oil transfer systems

- Ship-to-ship and ship-to-shore fluid transfer

- Dredging and reclamation projects (sand, mud, slurry)

- Seawater intake and discharge for marine facilities

- Port, jetty, and terminal loading systems

These applications require hoses with stable performance, long service life, and compliance with project specifications.

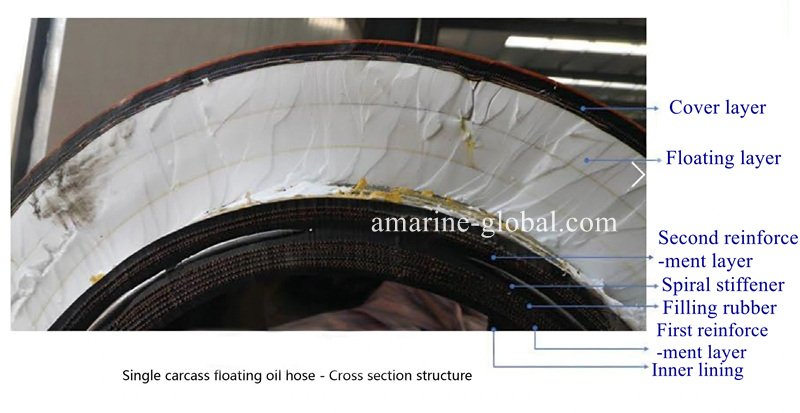

Marine Hose Structure (Engineering Overview)

A standard marine hose is a multi-layer composite structure, optimized for strength, flexibility, and durability:

1) Inner Lining

-Directly contacts the conveyed medium

-Oil-resistant, abrasion-resistant, or chemical-resistant rubber

-Selected based on fluid type, temperature, and concentration

2) Reinforcement Layer

-High-strength textile cords or steel wire reinforcement

-Provides pressure resistance, tensile strength, and dimensional stability-

-Designed to meet the required working and burst pressures

3) Outer Cover

-Resistant to seawater, UV, abrasion, and weathering

-Protects the hose in harsh offshore and port environments

-Floating marine hoses may include buoyancy layers to maintain stability on the water surface.

Working Conditions in Marine Projects

Marine hoses are designed for continuous operation in demanding marine environments, including:

- Constant exposure to seawater and salt spray

- Dynamic bending caused by waves, tides, and vessel movement

- Axial loads and tension in floating hose strings

- Internal pressure fluctuation during pumping operations

For engineering projects, hoses are typically specified with high safety factors to ensure reliability and reduce operational risk.

Standards & Procurement Considerations

Marine hoses for offshore and port projects are commonly manufactured according to:

— OCIMF guidelines (for oil and offshore transfer)

— ISO / EN rubber hose standards

— Project-specific technical specifications

Key procurement parameters include:

- Hose diameter and length

- Working and burst pressure

- Bending radius and reinforcement type

- End fittings and connection standards

- Service life and maintenance requirements

Why Choose Our Marine Hoses (For Engineering & Procurement)

Our marine hoses are developed specifically for offshore engineering projects and port infrastructure, with a strong focus on reliability, compliance, and lifecycle cost control.

Key advantages valued by EPC contractors and procurement teams include:

Engineering-grade design: Hose construction optimized for pressure, bending, and dynamic marine loads

Standards compliance: Designed in accordance with OCIMF, ISO, and project-specific technical requirements

Application matching: Dedicated designs for oil transfer, dredging slurry, and seawater systems

Customization capability: Diameter, length, pressure rating, reinforcement type, and end fittings tailored to project needs

Long service life: Reduced replacement frequency and lower total cost of ownership

These factors help minimize operational risk and ensure stable performance throughout the project lifecycle.

Conclusion

A marine hose is a critical component in offshore and marine engineering projects, where safety, compliance, and durability are non-negotiable. For project owners, engineers, and procurement professionals, selecting a properly engineered marine hose directly impacts system reliability and long-term operational cost.