When installing rubber fenders, especially long-profile or heavy-duty types, one simple yet important step can make a big difference: chamfering. Often overlooked, chamfering the edges of a fender helps protect against premature wear, cracking, and misalignment—particularly at the ends where stress concentrates.

What is Chamfering?

Chamfering is the process of cutting or shaping the edge of a rubber fender, usually at the ends, to create a beveled or rounded profile. This can be done at various angles (typically 45°) or radii, depending on the fender type and installation conditions.

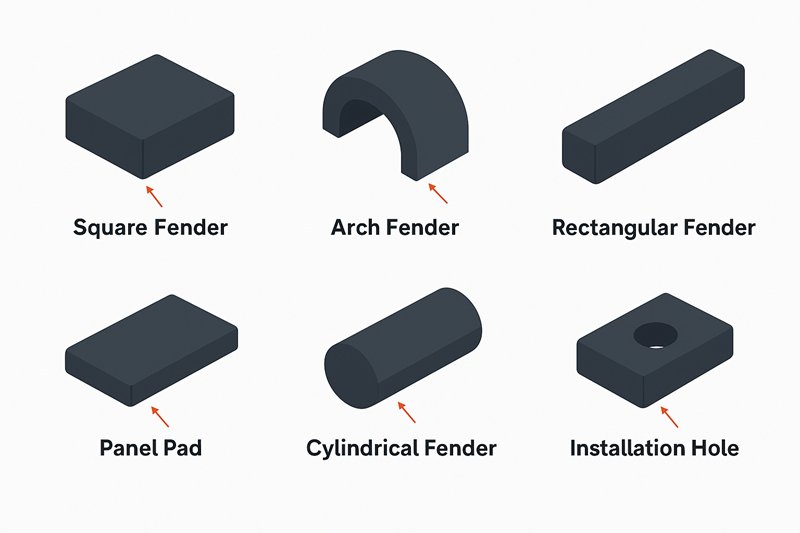

It’s commonly applied to:

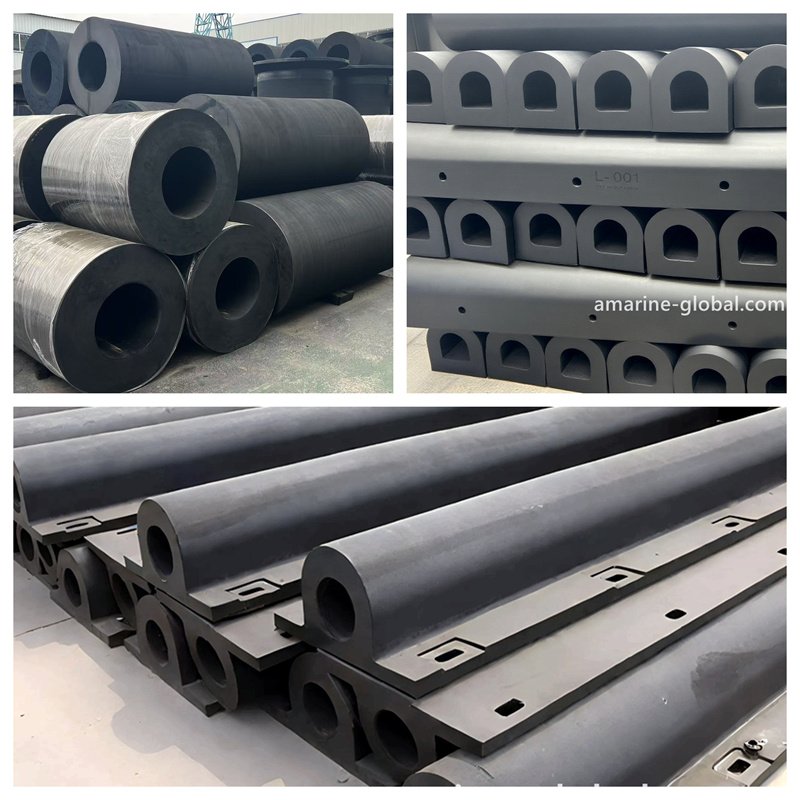

1) D-type, Wing-type, and cylindrical fenders

2) Fenders installed near corners or hull contact zones

3) Custom-length fenders with exposed ends

(The Cylindrical, D-type, and Wing-type fenders that our factory manufactures. )

Why is Chamfering Important?

Without chamfering, the sharp ends of a fender can:

— Tear or crack under pressure

— Catch on the ship hull during contact

— Look uneven or unprofessional once installed

— Create fitting problems at joints or transitions

By chamfering, you ensure:

— Smoother transitions at joints or corner areas

— Less risk of material damage

— More professional, clean finish

— Easier alignment with mounting surfaces

Common Chamfering Types

| Type | Description | Use Case |

| 45° Bevel Cut | Diagonal edge, most common | D-fenders, Wing fenders |

| Radius (Rounded) | Smooth curved edge | Hull-facing zones |

| Flat End Chamfer | Cut at a shallow angle | For surface leveling or weld-on parts |

How is Chamfering Done?

Chamfering is done before installation, usually in the factory, using:

— Cutting machines or manual tools for precision

— Molds in the case of mass production

— Custom cutting per order for tailored applications

In some projects, on-site trimming may be performed, but this method is less precise and is not recommended for heavy-duty fenders.

( Chamfer positions for various fender types. )

Chamfering may be a “small cut,” but it plays a big role in the durability, safety, and aesthetics of your rubber fender system. Especially for long or exposed fenders, proper edge treatment can mean the difference between years of reliable performance and early failure.

Need chamfering service for your fenders?

We offer custom edge finishing for all fender types to match your project’s needs. Send us your drawings or specs—we’ll take care of the rest.

Related reading: When and Why Pre-bending is Needed for Rubber Fenders →