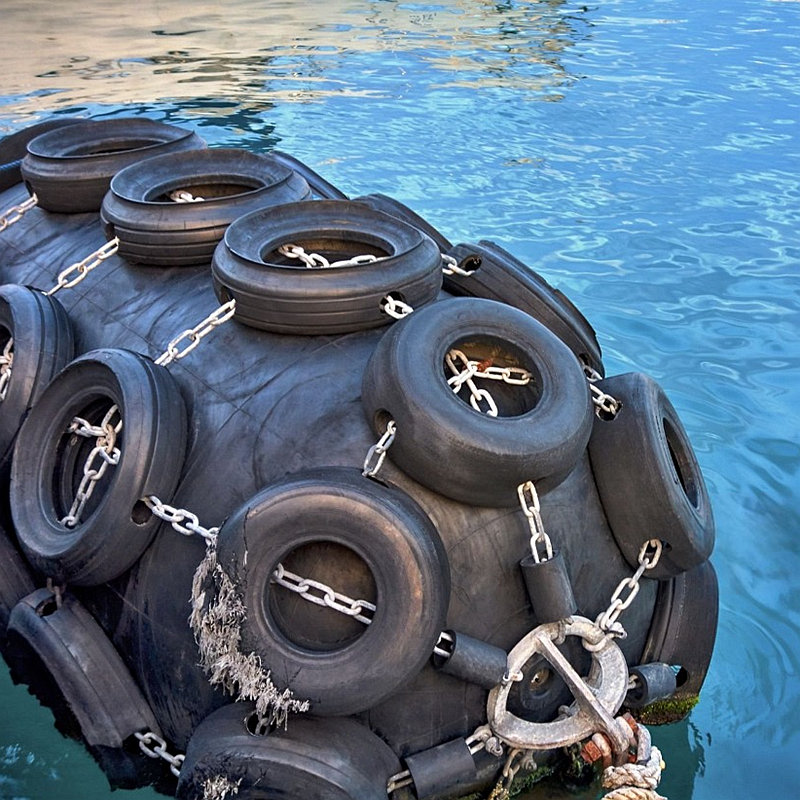

In marine construction, the performance of rubber fenders depends not only on material quality and design but also on proper installation. One critical yet often overlooked step is pre-bending. This process ensures that the fender aligns smoothly with curved structures, such as round piles or quay walls, thereby avoiding stress concentration and improving durability.

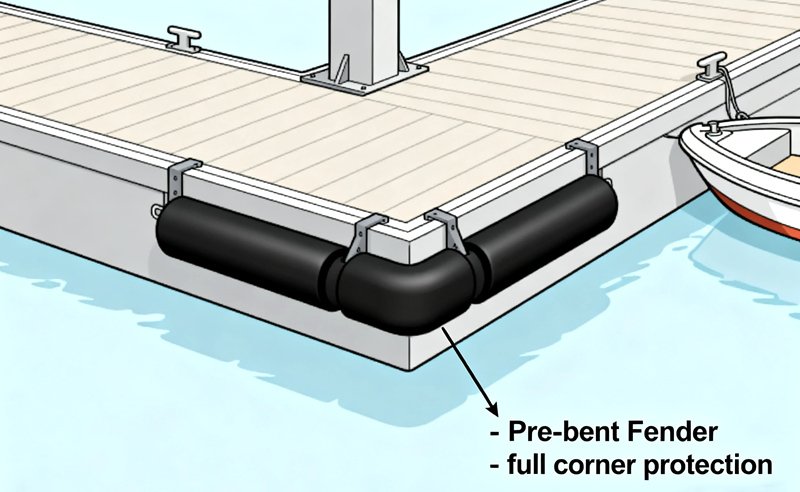

What is Pre-bending?

Pre-bending is the process of pre-forming a rubber fender into a curved shape that matches the contour of the installation surface. Instead of forcing a straight fender to fit a curve onsite—which can cause deformation or cracking—pre-bending allows for seamless integration and better surface contact.

When is Pre-bending Required?

You should consider pre-bending when:

1) The fender is to be installed on circular piles or rounded piers

2) The mounting surface has a noticeable curvature or arc

3) You want to minimize onsite bending stress

4) The fender length exceeds a certain span on a non-flat surface

Benefits of Pre-bending:

1) Improved contact between the fender and the structure

2) Reduced internal stress in the rubber body

3) Easier and faster installation on-site

4) Less risk of cracking, tearing, or adhesive failure

5) Enhanced lifespan of the entire fender system

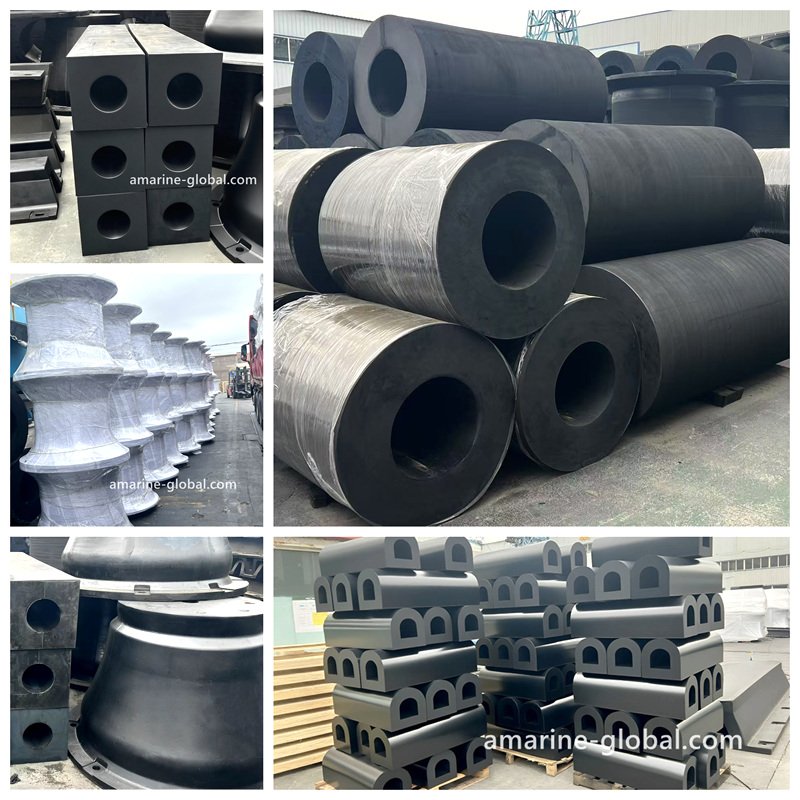

(Our factory has manufactured many types of rubber fenders, and all sizes can be customized.)

How is Pre-bending Done?

Pre-bending is usually carried out in the factory using:

— Molds or jigs tailored to the project curvature

— Thermal shaping (controlled heating to form the curve)

— Mechanical pressing in some cases

Manufacturers can also assist in calculating the correct bending radius based on drawings or on-site measurements.

Conclusion

Pre-bending may seem like a minor detail, but in the long run, it plays a major role in ensuring rubber fenders perform reliably under pressure. If your installation involves curved surfaces, pre-bending is not optional—it’s essential.

Not sure if your project requires pre-bending?

Contact our team with your drawings or structural details—we’ll help you determine the best pre-treatment approach.

Related reading: Chamfering in Fender Installation – Small Cut, Big Difference →